The modern world relies on vast networks for extracting, processing, transporting, and ultimately consuming hydrocarbons such as crude oil and natural gas. However, these resources come at a cost. Resources are finite, and it is difficult to extract carbon dioxide from the ground and release it into the atmosphere.

Rather than reduce humanity's dependence on hydrocarbons (which, depending on you, is either impossible, undesirable, or both), Terraform Industries' solution is to reduce electricity and air through a system called the Terraformer. is used to produce this resource. Today, the startup announced that it has commissioned its demonstrator Terraformer to produce synthetic natural gas for the first time.

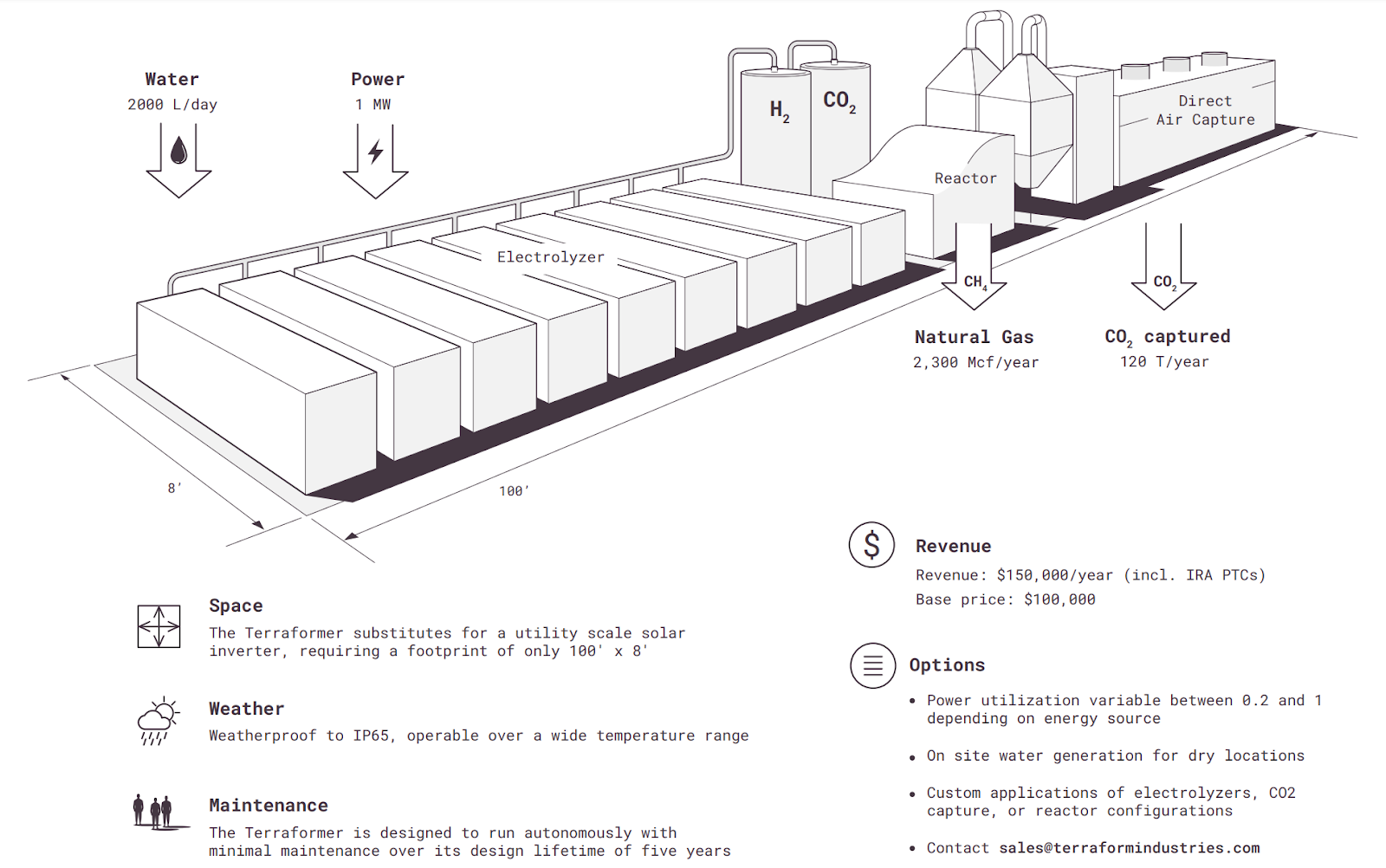

Roughly the size of two shipping containers, Terraformer consists of three subsystems. Direct air recovery system to capture CO2. and a chemical reactor that takes both of these inputs to produce pipeline-grade synthetic natural gas. The entire machine is optimized for 1 megawatt solar arrays.

As CEO Casey Handmer admits, nothing the company has done is “super original.” For example, electrolysis and the Sabatier chemical reactor are well-understood processes. However, the company was able to innovate its processes, including building its own direct air recovery system and adapting it all to run on a variable energy source: solar power. So while the origins of certain subsystems can be traced back to, say, the 19th century or the 20th century, the entire process is completely new.

Image credit: Terraform Industries

The result is some pretty impressive cost savings. Terraform says its systems convert clean electricity into hydrogen at a cost of less than $2.50 per kilogram of H2 (currently, green hydrogen costs in the range of $5 to $11 per kilogram). Mr. Handmer estimates that there is.) The direct air capture system also allows him to filter CO2 for less than $250 per ton, which is a world record, the company said in a statement.

The company said improvements are already underway to further reduce prices so that synthetic natural gas is cost-comparable to traditionally sourced liquefied natural gas. Much of it relies on the massive construction of cheap solar power and the necessary production of thousands of terraformers per year.

In fact, Handmer is an extraordinarily ambitious thinker, but it would be a mistake to think that his head is stuck in the clouds. He is keenly aware that without his strong business case behind Terraform, Terraform's plans will be doomed.

Image credit: Terraform Industries (Opens in new window)

“There's an idea that we've been working towards, which is that a lot of the great technologies to deal with the climate problem are fundamentally outside the scope of capitalism because they don't make money,” he said. Stated. “In fact, they spend more money than they earn. That makes it very difficult to scale. But if you can figure out how to make more money than you spend, You're in the tent of capitalism. It's just a system where money flows naturally. That's the important thing.”

Burbank, Calif.-based Terraform has agreements to sell small amounts of natural gas it produces to two unnamed power companies, but while the initial volumes are small, “this is a very important It's a big step,” Handmer said. “This shows that we have produced gas that meets the standards.”

The company is in ongoing discussions about prototyping or selling standalone electrolyzers as separate products, and producing liquid fuels other than methane. Terraform is also accepting pre-orders for the first production version of Terraformer. The ultimate goal is to augment factories to support structures that can do nothing but transform the world's energy system.